A QUALITY

FOCUS EVERY

STEP OF THE WAY

A QUALITY

FOCUS EVERY

STEP OF THE WAY

Laboratory testing

A series of critical tests are carried out as per standards to confirm the coat quality.

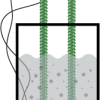

CHEMICAL RESISTANCE TEST

Bars are immersed in solutions per BIS 13620:1993 norms to test chemical resistance

SALT SPRAY RESISTANCE

Exposure to salt sprays is done as per ASTM-775 recommendations to test resistance to wet and corrosive environments.

RESISTANCE TO AN APPLIED VOLTAGE

The effect of electrical and electrochemical stresses on the bond and integrity of the coating is assessed as per BIS 13620:1993.

ADHESION OF COATING

ABRASION TEST

The resistance of the coating on coated panels to abrasion is tested by a Taber Abraser as per the procedure mentioned in BIS 13620:1993.

IMPACT TEST

Mechanical damage resist- ance is tested with the falling weight test as per BIS 13620: 1993.

COATING THICKNESS TEST

Coating thickness is checked using Coating thickness guage as per BIS 13620:1993.

COATING HOLIDAY TEST

Coating Holidays are using Pinhole detector as per BIS tested 13620:1993.

KNOOP HARDNESS TEST

Knoop Hardness Test is done using Coating Bar in Knoop Hardness Machine for checking hardness of coating as per BIS 13620:1993.

Focus on

Quality

Quality is controlled diligently from ingredients and processes to testing to

ensure perfect and uniform results.

in-house. Using 100% iron ore ensures an extremely low level of

tramp elements.

ensure consistent quality and precision. Sponge iron and liquid

metal undergo a long process of purification, strengthening and

other enhancements with automated machines. more…

in-house physical and chemical laboratories.

Sales: +91 8238079223